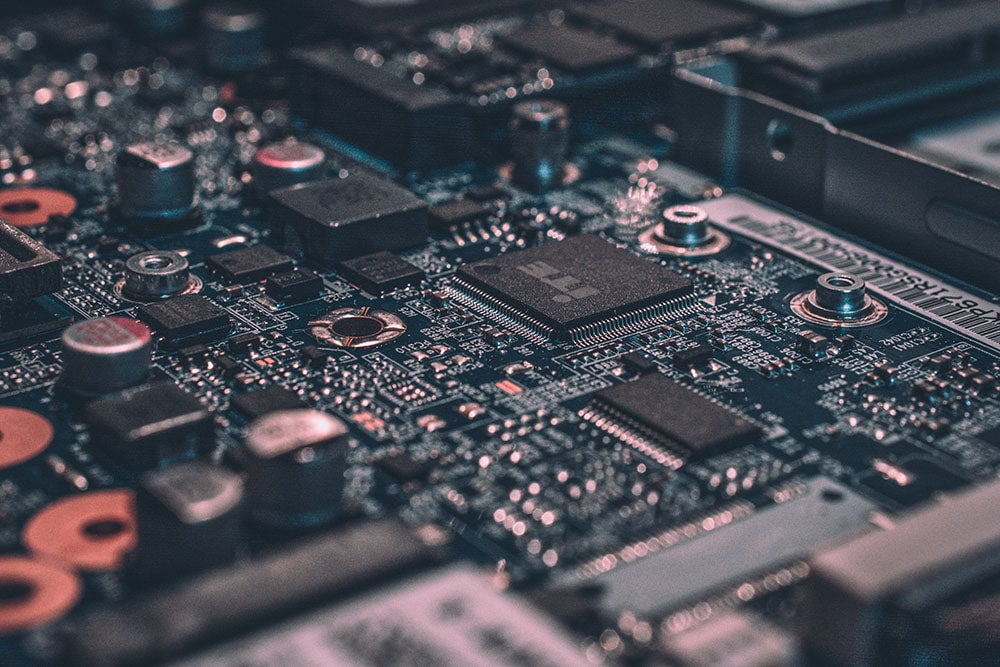

Heating is an inevitable part of using any electronic device. To prevent overheating and damage, these devices need a cooling system.

Researchers have nearly reached the limit of their ability to produce smaller, more compact, and quieter fans, which had been the only way to cool electronic components for decades. A number of innovative solutions have been created recently to cool electronics.

What Is Piezoelectric Cooling?

The creation of a cooling stream of air via piezoelectricity discharge, namely piezoelectric cooling, is one of the most effective of these novel electronics cooling solutions.

By combining the special characteristics of piezoelectric materials with their silicone sealant and surface coating process, piezoelectric fans provide strongly dependable solid-state forced convection remedies. They can greatly minimize temperatures and maintain heat flow inside the electronic devices.

This reliable and efficient cooling technology can perform in harsh environments where conventional fan would perform poorly.

Why Piezoelectric Cooling Is Crucial for Thermal Management

For high-current-intensity industrial appliances to operate properly, thermal control is essential. This is challenging to do in safety-critical systems because the cooling system's reliability must be far higher than that of conventional techniques. Also, there is a general need to enhance the rate of heat evaporation, lower operating temperatures, and increase durability in all devices.

Therefore, piezoelectric fans are introduced as a fault-tolerant, forced-cooling condensation solution for electric devices.

Types of Electronic Cooling Systems for Heat Removal

The cooling requirements of contemporary electronic systems are not being met by conventional cooling methods, which usually consist of air-cooled heating elements. As a result, several ways for cooling such devices have recently been thoroughly researched and used in a variety of thermal management devices.

These include absorption chillers, microchannel heat, infringing sprays, thermodynamic refrigerators, thermosyphons, heating elements, and electro-osmotic pumps. Both passive and active systems may be used to classify these cooling strategies.

Active cooling systems are powered by a pump or turbine for greater cooling capacity and enhanced performance, while passive cooling systems recirculate the hydraulic fluid using a capillary.

Active Cooling

Active cooling uses fans to dissipate heat from computer parts. It utilizes energy and cools a component directly. Fans, evaporative air-conditioning units, and refrigerated air conditioners like split systems are a few examples of operating cooling systems. The power, moisture, and capital these systems use vary.

Passive Cooling

Slowing down the pace at which an electronic component, such as a multicore or main circuit, operates is referred to as passive cooling. Active cooling systems typically outperform passive cooling systems.

How a Piezoelectric Fan Works and Its Advantages

The piezoelectric fan's cooling technology has various benefits, including high-temperature tolerance, a lack of electromagnetic fields, directed quick thermal management, power efficiency, longevity, and noise cancellation. These fans generate airflow by vibrating cantilevers instead of rotating blades. The piezoelectric material converts electrical energy into mechanical energy for this vibration effect using a thermoelectric cooler. Since thermoelectric cooling is less efficient, it is combined with piezoelectric cooling.

With the advancement of piezoelectric cooling fans, thermal engineers now have a highly effective cooling option.

The piezoelectric fan's greatest benefit is that it outperforms conventional fans in terms of positional accuracy, wind direction, and permanent magnet spillages by having a high-frequency content that prevents focused air from spreading, curbs magnetic leaking, and provides good channel capacity and quick wind speed.

Its air evaporative cooling is undoubtedly superior to that of conventional fans at the same rated power. It also features a straightforward design, a tiny footprint, little weight, an improved life span, and an automatic clamp when the power is turned off.

Best Applications for Piezo Fans

Following the advantages listed above, the top five uses for piezoelectric fans are as follows.

Tools for Telecommunications

For telecom firms, dependability and network uptime are essential. Because typical fan products are generally unreliable, especially for outdoor equipment, the majority of telecommunications equipment relies on big, heavy passive heat sinks instead.

LED Illumination

Light-emitting diodes (LEDs) need to operate for a long time to realize the financial benefits of solid-state lighting systems. Like with other electronics, an LED's life span is closely correlated with the temperatures it encounters. Maintaining the temperature variation is important for LEDs to operate for a long time. Reduced longevity results from higher temperatures. To prevent an early breakdown, many systems must utilize multiple LEDs operating at lower power levels than the LEDs can really withstand. An LED's life would be extended, and its performance would be improved, with forced convection cooling.

Aviation Actuators

Actuator dependability is crucial in the aircraft industry. Due to this, massive, obtrusive passive heat sinks are frequently employed for cooling actuators on airplanes. Although it is hefty and has a huge form factor, this solution is incredibly dependable. These enormous passive heat sinks are not always the best option for this application because weight and storage are limited on an airplane; instead, a smaller heat sink with dependable airflow would be desirable.

Electronics for MRI Rooms

Magnetic resonance imaging (MRI) rooms are kept quite chilly. This is because it's crucial to keep the electronics cold, and typical cooling fans can't be used due to the electromagnetic interference they produce. A conventional fan's magnetic field would disrupt an MRI scan and skew the results. Piezoelectric fans can be utilized in MRI machines and other heat-sensitive devices since they have no discernible magnetic field.

Defense Electronics

Thermal requirements for military equipment range from minus-55 to plus-125 degrees Celsius. The maximum temperature range for a top-of-the-line conventional cooling fan is minus-20 to plus-85 degrees, which is significantly lower than the military standard. Thermal cycling or running at the upper end of the temperature range has no effect on the life span of piezoelectric fans, which may work between minus-55 and plus-125 degrees. Furthermore, a piezoelectric fan will not be affected by the harsh, dirty conditions that are frequently seen in military equipment.

Increase Performance and Thermal Resistance With Boréas Technologies' Piezo Driver

The next wave of elevated piezoelectric fans is made possible by Boréas Technologies' ultra-low-power piezo drivers. With these high-voltage, low-power piezo drivers, you can improve the performance and thermal resistance of all your electronic devices. Learn more about our technology and its applications here.

Leave a comment